Advantages of the BSK®-Turbine

High efficiency

The special hydraulic shape of the BSK®-Turbine makes it possible: up to 2.8 kg O2/kWh

Advantage: significant savings in operating costs (More than 60 % of the energy demand of a wastewater treatment plant is spent on the aeration of the biological stages.)

Exemplary aeration and mixing performance

The special hydraulic design according to the “Francis-concept” allows not only an optimized aeration, but also the circulation rate is unique, even in deep tanks.

Made of stainless steel

No material is more suitable in wastewater than stainless steel: No corrosion and almost unlimited lifetime. Free choice of alloy is possible (AISI 304L, 316L etc.)

Durable construction

365 operating days per year and maximum daily service require extremely robust components.

BSK® drives provide the answer: Service factors up to 3.0 and double-bearing technology.

No efficiency loss

Design-immanent, no decrease of power input, high alpha (α) factor ≥ 0.9, no loss of efficiency in oxygen transfer capacity compared to fine-bubble aeration.

Minimal installation effort

No pipes no blowers and no housing/no complex civil works for compressed air units needed, no problems with condensated water

Easy maintenance

No maintenance components under water. The only maintenance is an oil change every 2-4 years (depending on oil quality). In case of repair: Easy disassembly without emptying the tanks.

Less spray and aerosols

Low splash height and channeled ejection of water causes less aerosols, no splash guard needed.

Fields of application

- Aeration and mixing of activated sludge in biological wastewater treatment plants (sequence batch reactors, traditional continuous systems)

- Aerobic sludge stabilization

- water treatment

Typical applications in the field of biological wastewater treatment:

-

Municipal wastewater treatment plants:

- Wastewater treatment plants for municipalities and cities

- Sewage treatment plants for hotels

- Wastewater treatment plants for military camps

-

Industrial wastewater treatment plants for the food industry:

- Dairies

- Fish canneries

- Potato processing industry

- Slaughterhouses

-

Industrial wastewater treatment systems for the non-food sector:

- Paper mills

- Textile mills

- Tobacco industry

- Rendering plants, etc.

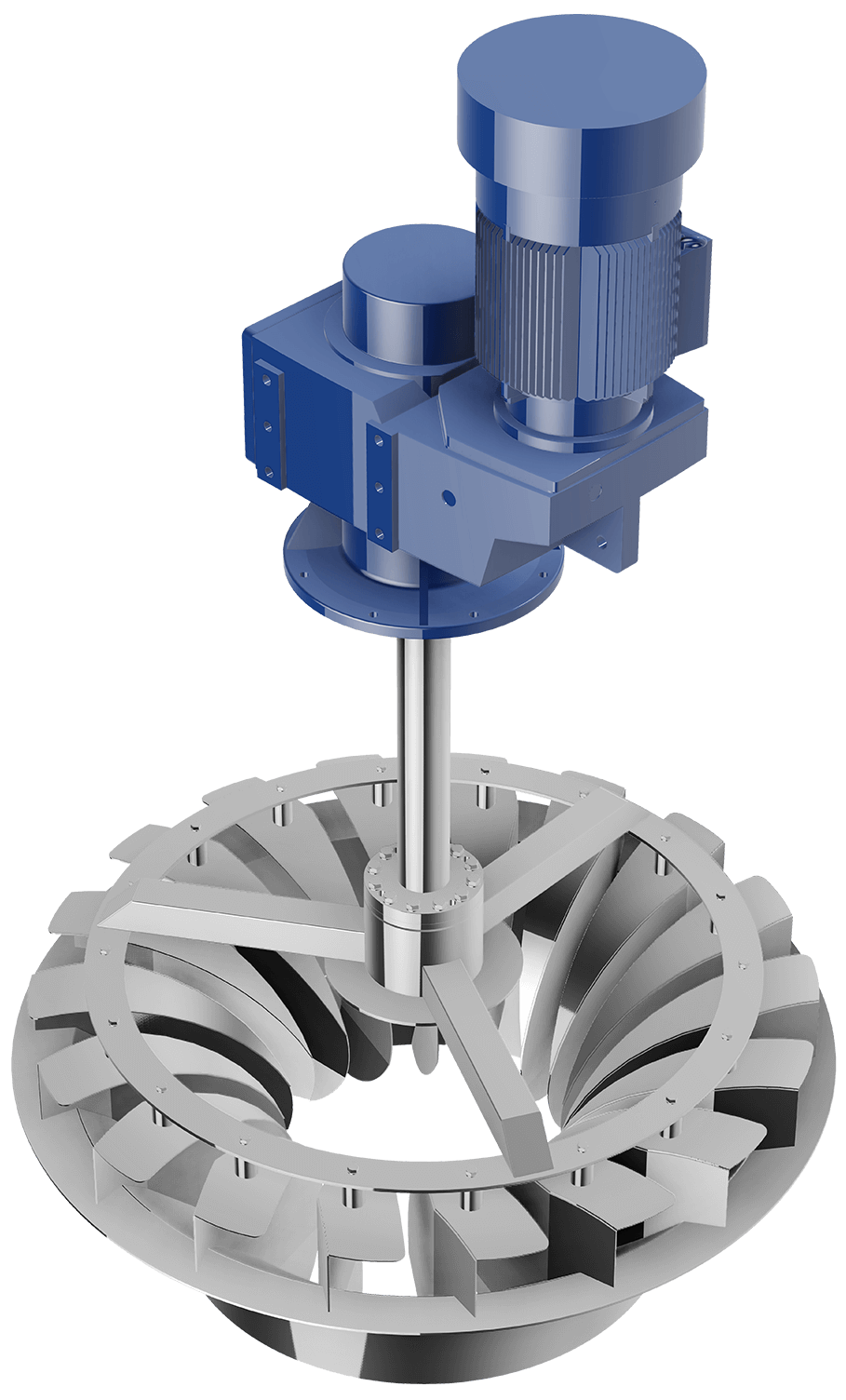

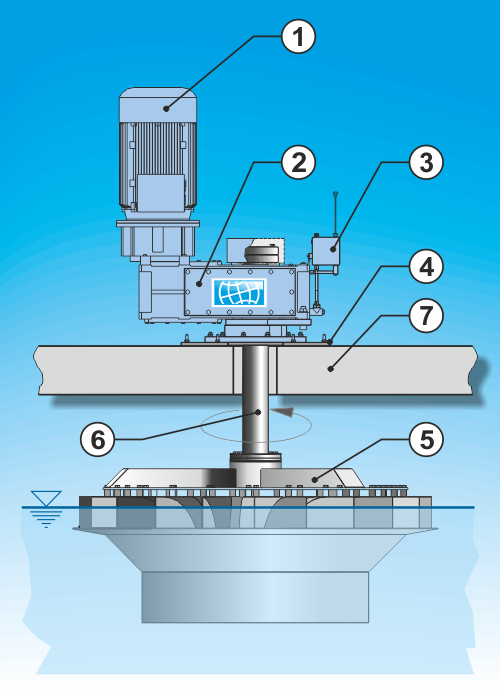

Construction details

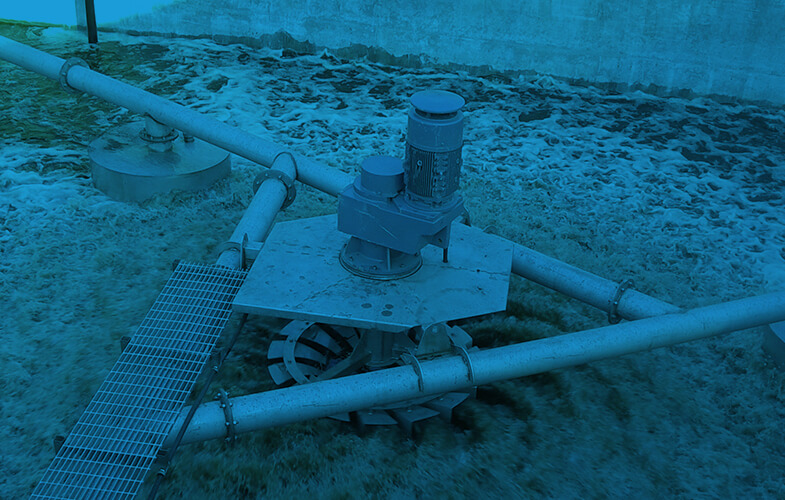

General Layout of the BSK®-Turbine surface aeration system

- 1 Three-phase motor

- 2 Flat gear unit

- 3 Oil reservoir

- 4 Baseplate for gear unit

- 5 BSK®-Turbine

- 6 Drive shaft

- 7 Fixed bridge or floating system

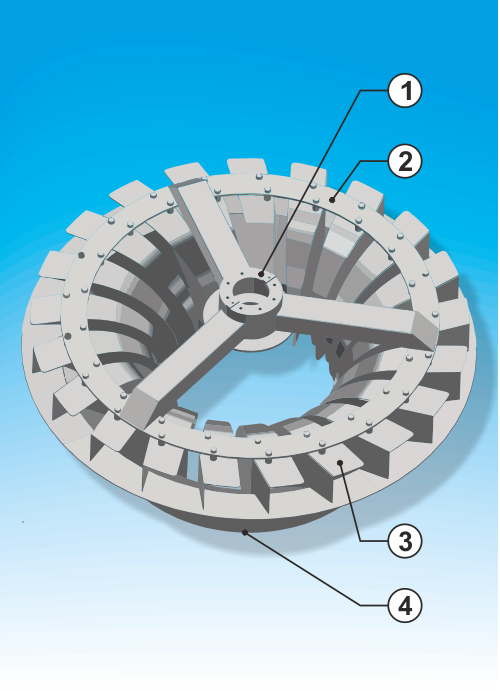

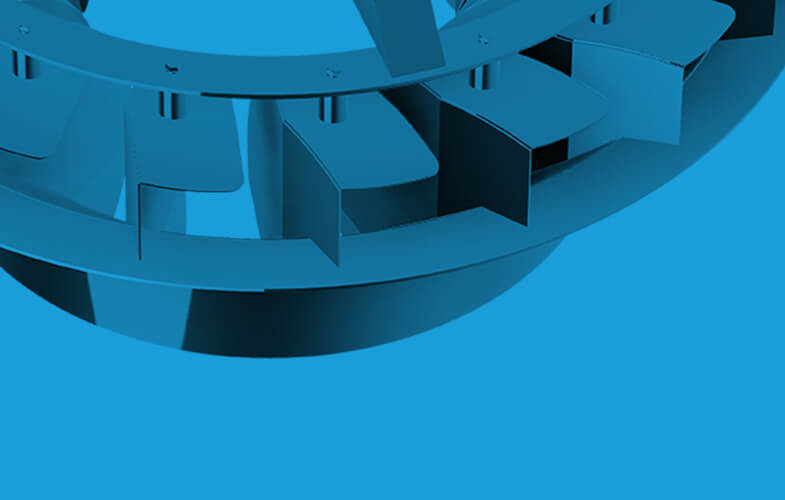

Components of the BSK®-Turbine

- 1 Connection flange

- 2 Crown ring

- 3 Conveyor blades

- 4 Baffle

(All parts are made of stainless steel)

Video

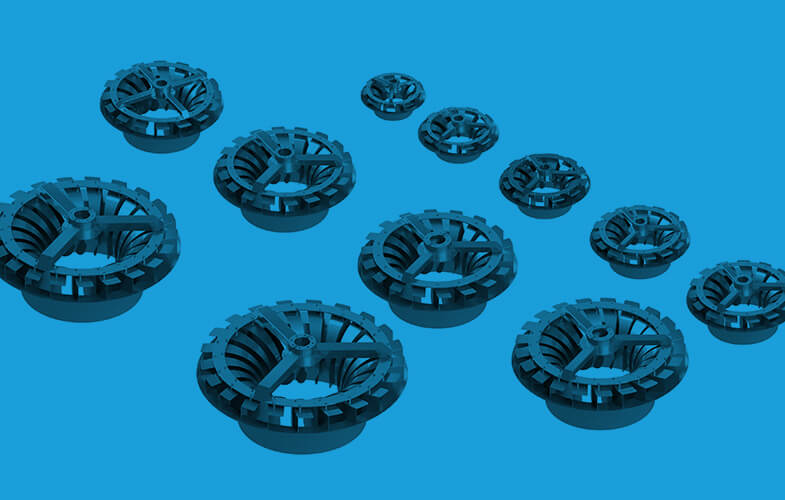

Versions / Sizes

Sizes

11 different standard sizes available: diameters from 900 up to 3,000 mm

Material

Manufacturing is possible in various alloys of stainless steel:

- stainless steel (AISI 304L)

- stainless steel (AISI 316L)

Different steel grade upon request

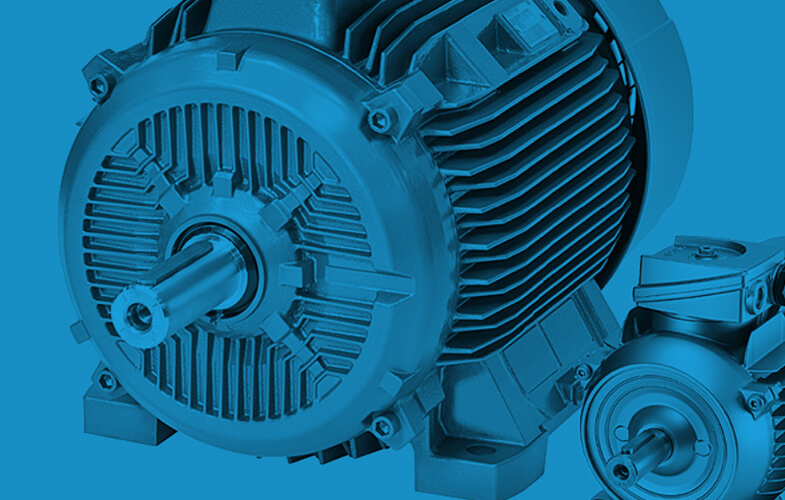

Drive system

Motor power from 5.5 kW to 130 kW, Standard efficiency class: IE3, on request: IE4

High-performance gear in industrial quality with hollow shaft or flanged shaft

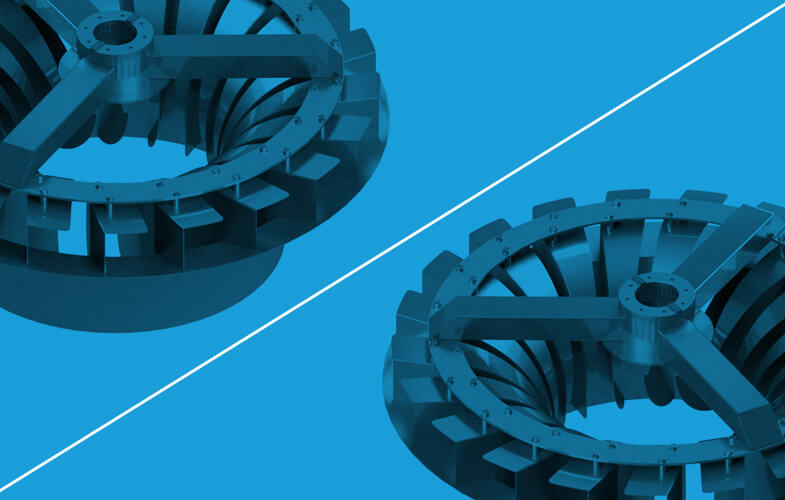

Direction of rotation

left- or right-handed available

Installation

Mounting on floating systems (adaptable in height according to different water levels, e. g. in SB-reactors) or fixed installation on steel or concrete bridges (at constant level)

Oxygen input

up to 308 kgO2/h

History

- Developed in 1960 based on proven “Francis”-design – testing program over several years

- 1990 continuous improvement process – highly efficient hydraulic design

- Based on the experience of the last 40 years, combined with the latest hydraulic models, a new generation (BSK®-Turbine) was developed

References

More than 2,000 BSK®-Turbines are in operation worldwide (including the references of our Swiss partner NORM A.M.C. AG), e. g.: